Solutions

Contact Us

- Tel : +86 18906343669

- Fax : +86 531 76778699

- Email : vivianxu@starringlw.com

- MSN:

- Skype:Whatsapp:008618906343669

-

Home > Geosynthetics > Geogrid > Fiberglass Geogrid

- Description

- Features

- Application

- Technical Parameters

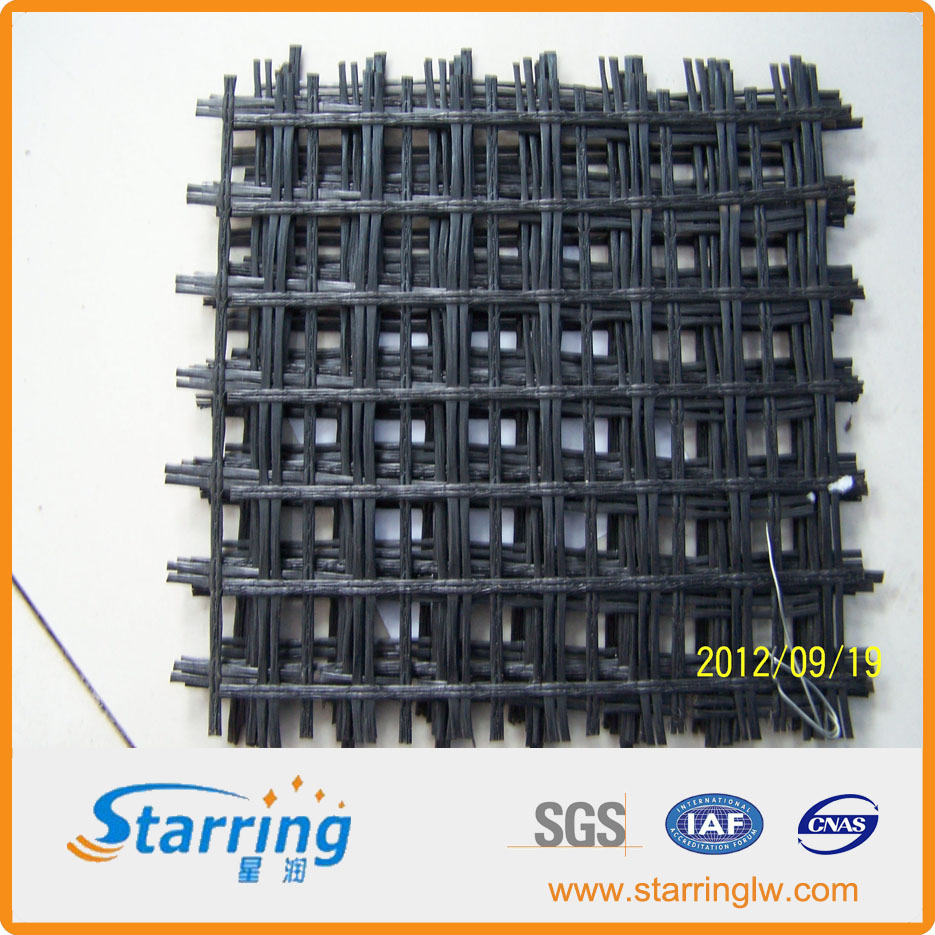

Fiberglass geogrid made of excellent reinforcement non-alkali fiberglass yarn and coated with excellent modified asphalt coating treament is a kind of plane network shape material. It is weaven into base material by using advanced warp knitter and adopts warknitted directional structure. Warp-knitting structure makes full use of yarn strength in textile and greatly improves geogrid's chemical performance makeing it have good tension resistance,tearing resistance and creep resistance.

1. Low elongation coefficient

2. No long term creeping effect

3. Fine compatibility with pavement materials

4. Good stability at high temperature

5. Alkali-resistant

6. Interlocking function

7. Consistency

1.To reinforce old asphalt concrete road surface and asphalt surface layer,and prevent damage;

2.To rebuilding cement concrete road surface into composite and restraining reflection caused by block contraction;

3.Used in road expansion and improvement project and creak caused by old and new combination position and uneven sedimentation.

4.It is used in soft soil base reinforcement treatment, sutible for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base.

Normal Type

|

Specification |

EGA 25-25 |

EGA 30-30 |

EGA 40-40 |

EGA 50-50 |

EGA 80-80 |

EGA 100-100 |

|

|

Strength(KN/m) |

Longitudinal |

25 |

30 |

40 |

50 |

80 |

100 |

|

Horizontal |

25 |

30 |

40 |

50 |

80 |

100 |

|

|

Break Elongation (%) |

≤3 |

||||||

|

Grid (mm) |

12.7×12.7 25.4×25.4 |

||||||

|

Breadth (m) |

1-6 |

||||||

Self-adhesive Type:

|

Specification |

EGA 40-40 |

EGA 50-50 |

EGA 60-60 |

EGA 80-80 |

EGA 100-100 |

EGA 120-120 |

|

|

Strength (KN/m) |

Longitudinal |

40 |

50 |

60 |

80 |

100 |

120 |

|

Horizontal |

40 |

50 |

60 |

80 |

100 |

120 |

|

|

Break Elongation (%) |

≤3 |

||||||