Solutions

Contact Us

- Tel : +86 18906343669

- Fax : +86 531 76778699

- Email : vivianxu@starringlw.com

- MSN:

- Skype:Whatsapp:008618906343669

-

Home > Geosynthetics > Geotextile > Woven Geotextile

- Description

- Features

- Application

- Technical Parameters

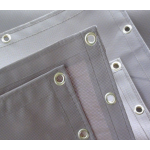

Woven geotextile is mainly use polypropylene (pp)as raw materials. After extruding, film slitting, stretching, flat yarn(single yarn, film splitting yarn) is knitted into geotextile.Woven geotextiles has high strength and can keep enough strength and elongation in dry and wet condition. It has long term corrosion resistance in the soil and water with different PH; There are gaps between flat yarns, making it has excellent water permeability performance. Due to its excellent microbiological degradation resistance, the geotextile will be free from damaged by micro-organism and worm. The material is light and soft, so it is convenient to transport and install.

1.Excellent drainage performance

2.High strength,excellent tenacity

3.Anti-aging,anti-acid and alkali

4.Excellent anti-microbiological degradation

5.Creep, corrosion and abrasion resistance

6.Safe and easy for construction

1.Reinforcement: Woven Geotextile fabric can be used in the constructions of highway, railway, airport, dam, prevent slope dike, retaining wall, etc. to improve stability.

2.Protection: Woven Geotextile fabric can prevent the bank from eroding by wind, wave ,tidal and rain. Used for the projects such as revetment, slope protection and bottom protection, anti-soil erosion,etc.

3.Filtration: Used as filtering layer of dike, the dam, river and coast stone , slope, retaining wall to prevent sand grain through and allow freedom through of air or water.

|

NO. |

Item |

Index |

|||||||

|

20-15 |

30-22 |

40-28 |

50-35 |

60-42 |

80-56 |

100-701 |

|||

|

1 |

Break Strength KN/m≥(LD) |

20 |

30 |

40 |

50 |

60 |

80 |

100 |

|

|

2 |

Break Strength KN/m≥(TD) |

15 |

22 |

28 |

35 |

42 |

56 |

70 |

|

|

3 |

Break Elongation %≤(LD,TD) |

28 |

|||||||

|

4 |

Trapozoidal Tearing Strength KN≥(LD) |

0.3 |

0.45 |

0.5 |

0.6 |

0.75 |

1.0 |

1.2 |

|

|

5 |

Burst Strength KN≥ |

1.6 |

2.4 |

3.2 |

4.0 |

4.8 |

6.0 |

7.5 |

|

|

6 |

Vertical Permeability Coefficient cm/s |

10-1 _ 10 -3 |

|||||||

|

7 |

Sieve Size(O95.)mm |

0.08-0.5 |

|||||||

|

8 |

Mass Weight g/m2 |

120 |

160 |

200 |

240 |

280 |

340 |

400 |

|

|

9 |

Variation% |

±10 |

|||||||